The DPRO-60 Radioactive Densitometer is used for continuous on-line non-contact measurement of the density or concentration of liquids, suspensions, bulk materials, airborne solids and sludge in pipelines and containers. Such as all kinds of pulp, sewage sludge, aluminum, mining, chemical, acid, alkali, salt solution and suspension concentration measurement. Application in extreme conditions such as high temperature, high pressure or vacuum, corrosion, abrasion, high viscosity, highly toxic media. Because the measurement is non-contact, easy installation, no downtime, good repeatability.

Measurement Principle

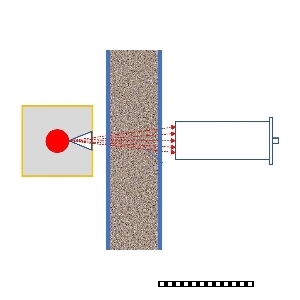

The DPRO-60 Radioactive Densitometer uses the physical principle of attenuation when gamma ray pass through a substance{exponential attenuation law}:since the container size is fixed, the density/concentration of the measured object is the only factor that affects the measurement results after the selected radioactive source is selected.

The DPRO-60 Radioactive Densitometer consists of a radioisotope, scintillation detector and intelligent transmitter sealed and installed in the source tank. The source tank is installed on one side of the pipe and the detector is installed on the opposite side. Gamma rays from radioactive isotopes are picked up by radiation detectors after passing through slits in the source tank and then through pipes and process media. When the density of the process medium changes, the signal intensity received by the detector changes accordingly. With the increase of medium density, the detector signal intensity decreases. On the contrary, the signal strength increases. The signal received by the detector is transmitted to a smart transmitter through a cable and converted into a corresponding density value or concentration value. If the flow signal can be connected, the system can also realize the on-line measurement of mass flow.

Split and One-piece Instrument Structure

Transmitter and Detector are installed separately.

Transmitter is integrated into the Detector

Radioactive Source with Pneumatic Lead Canister.

Radioactive materials are tightly enclosed in double-layer stainless steel sleeves, under high temperature, high pressure, strong impact and other extreme conditions will not leak out. CS-137 with different activity can be selected according to different measurement tasks. The source is semi-permanently fixed in the lead canister, and the resulting rays are directed at the detector through slits in the canister. Lead tanks are designed and manufactured according to the activity of radioactive sources to ensure that the radiation received by workers is far below the national standard. The lead can with pneumatic actuating switch can be locked in both on and off positions. The switch position is not in the same direction as the ray outlet to reduce the radiation exposure of maintenance personnel. Manual switching mode can also be switched

Product Features

Configuration 4.3 inch HD LCD screen, Chinese interface, simple operation, smooth operation.

Advanced friendly user interface, with detailed calibration, measurement, diagnostic information.

The magnetic switch button can be used to operate the instrument without opening the cover, especially for dangerous applications.

Optional density, concentration, mass flow and other measurement output mode.

Intelligent instrument, with temperature monitoring, fault self-diagnosis, radioactive source attenuation automatic compensation and other functions.

Powerful extension function, support manufacturers remote diagnosis, remote debugging.

Through PROWIN debugging software, the system parameters can be backed up and restored with one key to ensure data security.

Instruments and radioactive sources are controlled remotely, further improving factory automation and safety.

Market/Application

Ore pulp: aluminum ore, copper ore, gold ore, potassium salt ore, phosphate ore, coal mine, calcium ore, limePaper pulp and paper making: white liquor, black liquor, green liquor

Water treatment: mudChemical industry: acid liquor content, polymer, synthesis of ammonia and urea

Petroleum refining: crude oil density, finished oil densityFood:soy sauce,ketchup,orange juice, amylum, syrup