LPRO-90 Radioactive Material Level Meter raises the standard for non-contact level measuring systems. This simple, reliable, non-plug-in measurement system can be used to monitor and control the level or interface of liquids, slurries, and solids in a variety of reactors, containers, and silos. The measurement is not affected by the size and shape of the container, nor by high temperature, high pressure or vacuum, corrosion, wear, steam and dust. Due to the use of highly sensitive scintillation detector, coupled with the detailed and accurate design of professional and technical personnel, under the premise of ensuring the safety of users, to achieve stable, continuous and reliable measurement of material level.

Measurement Principle

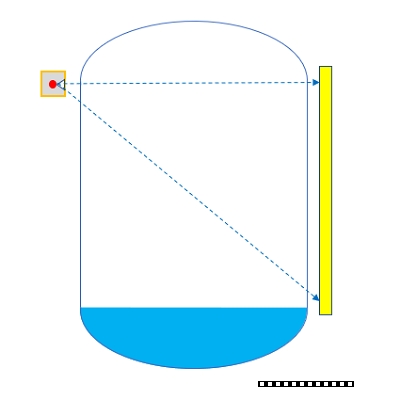

LPRO-90 Radioactive Material Level Meter uses the physical principle of attenuation when gamma rays pass through the material{exponential attenuation law}:when the container size is fixed, after determining the radioactive source, the high of the material in the container is the only factor affecting the measurement results.

LPRO-90 Radioactive Material Level Meter is composed of shielded radioactive source, scintillation detector and intelligent transmitter. The radioactive source is installed on one side of the container and the detector is installed on the opposite side. Gamma rays pass through the container and process medium and are picked up by the detector. When the height of the process medium changes, the signal intensity received by the detector changes accordingly. When the material level rises, the detector signal intensity weakens. On the contrary, the signal strength increases. The intelligent transmitter converts the electrical signal transmitted from the detector into the corresponding material level value.

Various Meters Configuration and Combination

Transmitter and Detector are installed separately.

Transmitter is integrated into the Detector

Typical Installation Sketch Map

Conventional container

Long and thin container

Thick wall container

Radioactive source with Pneumatic Lead Canister.

Radioactive materials are tightly enclosed in double-layer stainless steel sleeves, under high temperature, high pressure, strong impact and other extreme conditions will not leak out. According to different measurement tasks, different types and activities of radioactive source can be selected. The radioactive source is semi-permanently fixed in the lead canister, and the resulting rays are directed at the detector through slits in the canister. Lead tanks are designed and manufactured according to the activity of radioactive sources to ensure that the radiation received by workers is far below the national standard. The lead can with pneumatic actuating switch can be locked in the on/off position. The switch position is not in the same direction as the ray outlet to reduce the radiation exposure of maintenance personnel. Manual switch mode can also be switched.

Product Features

Configuration 4.3 inch HD LCD screen, Chinese interface, simple operation, smooth operation.

Advanced friendly user interface, with detailed calibration, measurement, diagnostic information.

The magnetic switch button can be used to operate the instrument without opening the cover, especially for dangerous applications.

Diversified instrument configurations, to meet the measurement requirements of different sites.

Intelligent instrument, with temperature monitoring, fault self-diagnosis, radioactive source attenuation automatic compensation and other functions.

Up to 20 material level control points can be calibrated to meet the high precision measurement requirements.

Powerful extension function, support manufacturers remote diagnosis, remote debugging.

Through PROWIN debugging software, the system parameters can be backed up and restored with one key to ensure data security.

Instruments and radioactive sources are controlled remotely, further improving factory automation and safety.

Market/Application

Coal chemical industryAlumina

SteelOrganosilicone

Mineral separationChemical fertilizer

Titanium dioxidePaper slurrying

Refining and chemicalPolycrystalline

PP/PE/PS/PVC/ABS/PTA/PETTDI/PDH

TRA-9861 Transmitter

DET-9000 Detector

Continuous measurement of powder height in horizontal polymerization caldron in a chemical plant.

The material level of flash tank in an alumina plant is continuous.