PPRO-80 Radioactive Material Level Switch can be used for liquid, mud and solid limit monitoring in a variety of reactors, containers and silos. The measurement is not affected by the size and shape of the container, nor by high temperature, high pressure or vacuum, corrosion, wear, steam and dust. Thanks to the use of highly sensitive scintillation detector, coupled with the calculation software of radioactive sources based on big data, so that ensure the radioactive activity is smaller and the radiation protection is simpler and safety is better.

Measurement Principle

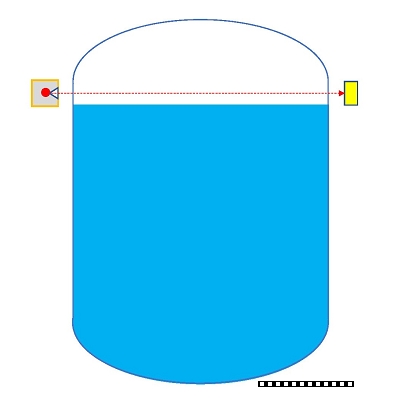

The measurement principle of PPRO-80 radioactive material level switch is based on the fact that gamma rays are absorbed by objects as they pass through them. If the object is between the source and the detector, the intensity of the gamma rays received by the detector will be reduced, and the amplitude of the electrical signal will be reduced, which is indicating that the object has reached the desired height. The pulse electrical signal is amplified by the micro circuit and output in the form of relay contact on or off, which is used for alarm or production process control.

Installation Sketch Map

Conventional Container Installation

Thick Wall Container Installation

Features

On-line measurement, real-time process control.

Real-time measurement can make the results timely feedback and thus achieve continuous process control.

Low maintenance and high reliability.

Since there is no contact with media or moving parts, long-term stable measurement can be achieved. No parts contact media, no clogging, corrosion or abrasion problems.

Low installation cost.

Installation can not end the process operation, no need to punch in the equipment.

High precision and repeatability.

After correct installation and debugging, the measuring accuracy can reach millimeter.

Easy installation and debugging.

Installed outside the container for quick debugging and calibration.

Self-diagnosis or process alarm.

Two independent relay outputs can be set by the user for process (material level) alarms or system diagnostic alarms.

Two detectors can be connected at the same time to output high or low material level alarm.

Solve extreme and difficult application problems.

High temperature - process temperature has no impact on measurement.

High pressure or vacuum - suitable for all pressures.

Corrosion, abrasion, high viscosity - non-contact measurement.

Highly toxic or viral - no connection to process, no leak point.

With agitator, baffle, coil or other internal member - with proper configuration, obstructions in the container will not affect the measurement.

The structure of the inner wall of the container, the glue hanging, the vapor density in the container - can be compensated by the configuration of the instrument.

Split and One - piece Instrument Structure.

Transmitter and Detector are installed separately.

Transmitter is integrated into the Detector.

Market/Application

Coal chemical industryAlumina

SteelOrganosilicone

Mineral separationChemical fertilizer

Titanium dioxidePaper slurrying

Refining and chemicalPolycrystalline

PP/PE/PS/PVC/ABS/PTA/PETTDI/PDH

TRA-9861 Transmitter

DET-8060 Detector

High material level control of ash lock bucket in coal gasification unit of a chemical plant.

Low material level control of ash lock bucket in coal gasification unit of a chemical plant.